Working together on high-quality precision products

- Nieuws

- Employers

- 13 February 2026

- 5 minutes

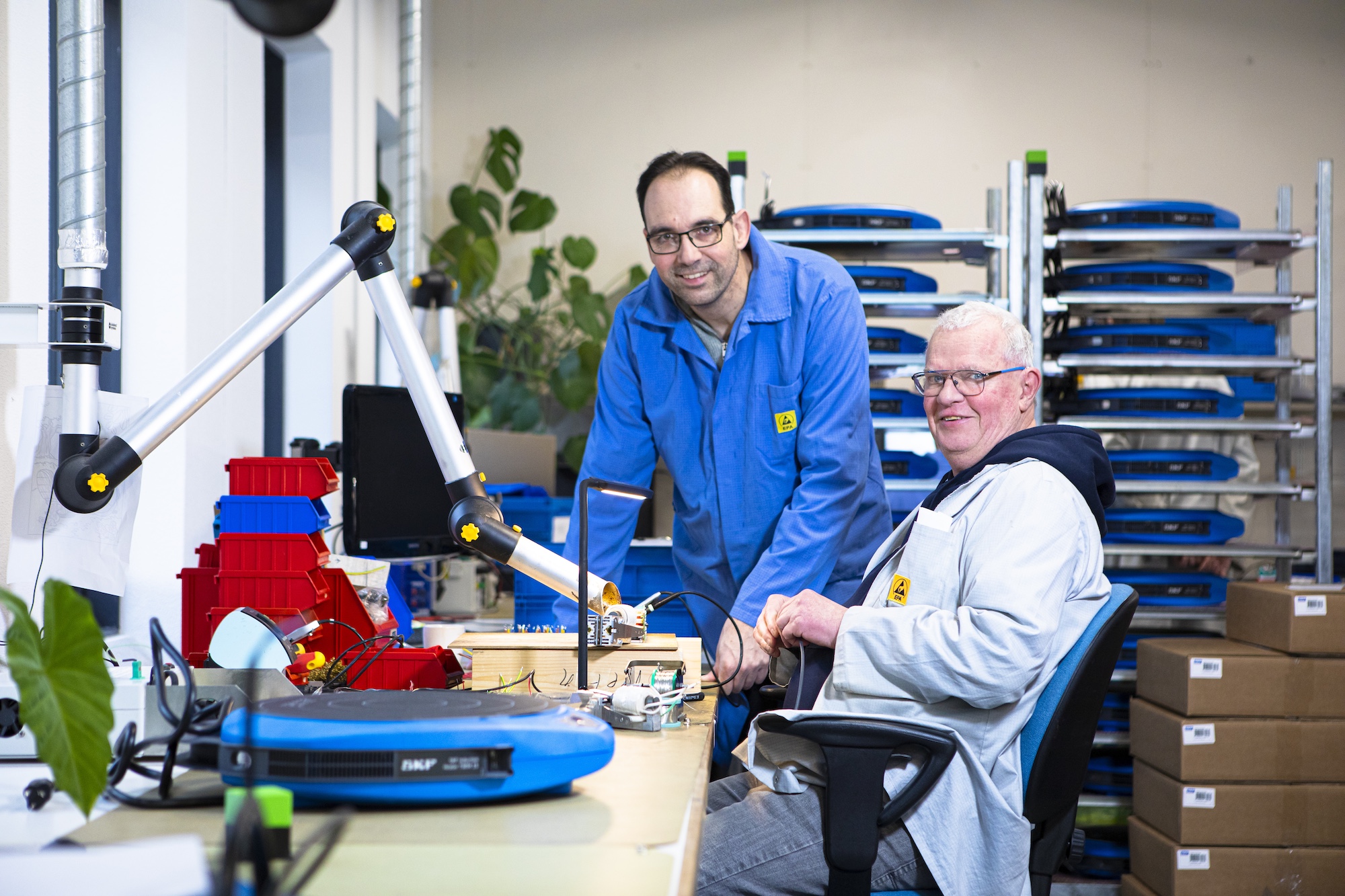

Since 2019, Werkse! has been delivering Assembly employees at the Delft high-tech company HedoN. After six years, we can speak of a fruitful cooperation. We visited the Werkse! team at HedoN and spoke with manager Richard van der List of HedoN and Werkse! employee Peter Dessens. ‘Work! Helps us extremely well with the assembly of our precision products.’

HedoN is a high-tech company that has been developing and producing electronics and software for various markets since 1979, including offshore, medical infrastructure, chemotronics and green energy. Operational manager Richard van der List: ‘We work completely tailor-made. It involves newly developed devices and technology, which exactly matches the wishes of our customers. They are looking for technological solutions to make their work processes run as smoothly as possible and set high demands.’ For production, HedoN works with a number of permanent specialists, a variable number of TU students who can be deployed flexibly and seconded employees of Werkse!.

Scalable

Richard: ‘The collaboration with Werkse! Started around 2019. We were looking for workers who could work very precisely and carefully and we wanted socially responsible corporate. That’s how we got to Werkse! Rightly. Through them, on the one hand, we could ensure qualitative assembly of our products, and on the other hand, help people with a support request to work.’ In the initial period, Werkse! employees were trained to work on one specific product, an induction heater – a device with which metal parts (bearings, bolts) of an industrial machine can be heated. Richard: ‘We liked that so much that we now also use the Werkse! team in the assembly of other devices. That happens for the most part here at HedoN, a smaller part becomes at Werkse! Done and so gradually the work expands.’ The useful of Werkse’s commitment! Is according to Van der List that it is scalable: ‘That means that we sometimes need more, sometimes fewer people, depending on demand. And that is possible at Werkse! Is very pleasant.’

iDuctor

Peter Dessens is part of the Werkse! team. He has been with Werkse for 48 years! Employed, mainly in secondment positions. From 2021 he works seconded at HedoN. Peter is currently working on the assembly of a manual induction heater – the iDuctor – with which, for example, rusted (wheel) bolts and nuts can be safely heated in garages to loosen them more easily. Peter: ‘Very nice and accurate work. At my workplace I have all the necessary parts of the device: circuit board, cables, coils, plugs, soldering machine. First of all, I check the circuit board. If it’s good, I solder the cables and plugs on it, and put everything together. That’s a whole series of actions until the entire interior is ready. Other colleagues then place that in the housing.’

Proud

Peter is proud of his work, especially when he can admire the final product. Recently he saw the iDuctor again on Discovery Channel, where it was used to heat the wheel nuts of an old car: ‘I didn’t know what I saw! Damn, that’s my device they work with on TV! I loved seeing that.’ Peter’s colleagues from Werkse! Working on another induction heater, a mobile device that allows you to accurately heat steel bearings so that you can mount them without damage. This is widely used in mechanical engineering, on shipyards and the like. Richard: ‘In part, that is specialist work, such as laying copper wrap in the housing of the device. The Werkse! employee who does this has therefore obtained a wrapping certificate here.’

Perfect

Supervision and control of the work is a fixed routine within HedoN. Richard: ‘So this applies not only to the Werkse! team, but all intermediate and final products are checked here by default. In our work, you can’t leave anything to chance.’ Peter agrees: ‘I myself am a huge Pietje Precies. It really has to be right, otherwise it has to be done again. It has to be perfect, that’s what we stand for!” Clothing, furniture and carpeting in this workspace is anti-static and dissipates static electricity to protect the sensitive electronics. Richard: ‘If something is damaged by an electric shock, you can’t see from the outside. That is why we are doing this preventively.’

Development

The employees of Werkse! Learn technical skills, work accurately and structured, collaborate in a professional production environment and develop craftsmanship.

Richard: ‘In addition to a manual that describes what to do, the employees are guided from start to finish. When assigning work, we look at what they can handle per person. We start with a simple action, and then it becomes more and more complex step by step.’ Peter, with his long experience and great accuracy, will be assigned multiple tasks. The other employees are currently on one specific product and help each other where necessary. In any case, the mutual atmosphere is good. Peter: ‘It’s nice here. There is certainly room for a chat or a joke. And if you have any questions, you can always contact Richard or one of the other HedoN people. Great!’

Do you want to receive the latest news?

-

Share article